Maximising Contract Drying

18TH OCTOBER 2019

Mr Robin Turney of Pools Barn Farm, Warwickshire, runs a farming and farm business consultancy company – Robin Turney Ltd, and also dries and stores grain for local farmers and United Oilseeds. For this harvest he asked Perry to help upgrade his existing storage and drying system from a floor drying system, to include a continuous flow drier in order to maximise his opportunities to contract dry and store.

He now has a straight forward system incorporating a 12m trench intake with a drive over grid (fabricated by Mr Turney), the intake bunker also doubles up as a wet holding area and can hold approximately 150 tonnes of product. This not only saves a considerable amount of money compared to having a wet storage bin and additional handling, but also makes the plant easier to operate. The intake pit is inverter controlled within the panel (designed and supplied by Perry). From the intake, the grain then passes through a 60tph aspirator cleaner before being lifted into the 30tph M410 drier via a 60tph double lift elevator and a 60tph flow & return store conveyor. Anything not fed into the drier is returned back to the pit.

Once the grain has been through the drier it is transported to the stores by two angled conveyors that follow the angle of the roof, where the grain is then passed in to top conveyors which carry the grain down the apex of the stores. The plant was installed by Darren Rouse Technical services and the electrical system was designed and installed by Hadley Electrical Contractors Ltd.

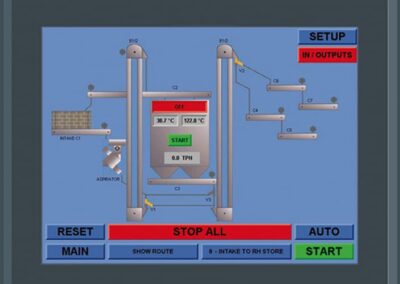

The drier has been fitted with side mounted fans to allow it to fit into the available gap between two existing buildings and the whole system is controlled using the Perry’s PLC drier and plant control panel. This touchscreen PLC panel has been designed and programmed by Perry engineers and is capable of controlling up to ten machines as standard along with the drier. The panel displays a mimic of the complete store as well as having multiple automatic routes available.

Mr Turney is expecting to put an average of 6,000 tonnes of wheat, rape and pulses per annum through the drier, and has the capability to store up to 10,000 tonnes of crop at any given time. Over the next few months the finishing touches were completed by adding a roof over the drier and intake so that the drier can remain operational throughout the year.

For more information please contact Perry on 01404 890 300

For more information on Mr Turneys drying and storage facilities please contact Mr Turney on 07720 899944

Hadley Electrical Contractors Ltd – 07973 326956

Darren Rouse Technical Services – 07768 231819