Commercial Sweep Augers

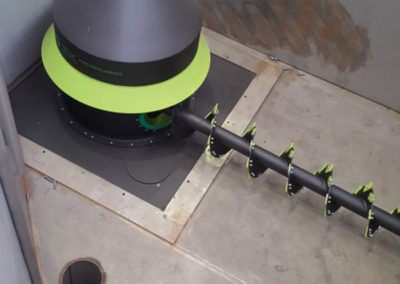

Perry can supply a range of industrial/commercial sweep augers (also known as Industrial grain reclaimers & FIFO unloaders), that are ideally suited to large farms and commercial grain stores. The sweep augers are designed to completely empty the bottom of flat silos or warehouses that store cereals, seed or pulses.

Key Points

Perry are suppliers of ODS industrial specification sweep augers which are the ideal solution for the removal of the grain once the silos are fully discharged by gravity. The range is comprised of four models, XS, M, FT & Twin.

Standard capacities range from 35m³ up to 800m³ and are designed to handle a wide range of products. Centre support frames are available in a range of sizes allowing for gravity discharging up to 2,000m³/hr.

The range of sweep augers can be installed in silos from 6 meters up to 42 meters in diameter. A reliable, fixable way to discharge silos, for small scale systems to quay side installations.

The range includes reclaimers for silos holding difficult to discharge products such as meals and woodchips.

Suitable Products

- Cereals (Wheat, Maize, Barley)

- Oleaginous (Soya Seeds, Sunflower Seeds, Rapeseed)

- Soya meal

- Wheat bran

- Paddy

- Nuts

- Wood pellets

- Plastic pellets

- Meat meal

- Saw dust

- Sludge

- Coal

- Plastic waste

- Sliced ice

- Fly ash

Capacities

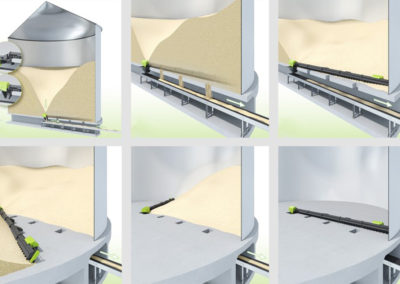

Design

These modular sweep augers have been designed to be quick and easy to install on site. The heavy-duty build prevents bends appearing at the front of the product pile, giving you a more even discharge, in turn reducing the stress and pressure on your silo & sweep auger.

The beams have been designed to be exceptionally rigid and heavy-duty, and the wheels are perfectly balanced. This helps ensure product longevity.

Contact us today to discuss your Storage requirements

Call us on +44 (0)1404 890300 or email [email protected]

PERRY DURING COVID-19

Managing Director, David Perry, said “It is imperative that our British farmers are able to continue to support this country through these uncertain times, as a company we aim to support them every way we can with the help of our trusted dealer network. From new...

TRENCH AND MECHANICAL INTAKE PITS: SELECTING THE CORRECT INTAKE CONFIGURATION FOR YOUR FACILITY

When considering which type of mechanical intake system to use, the first thing to consider is the type of products to be handled. If the products are all free flowing such as cereals, then a chain and flight conveyor system will...

SEASONS GREETINGS FROM PERRY OF OAKLEY LTD.

Wishing you a fantastic festive period, and a Happy New Year, from all at Perry! Our factory will close at 5pm on Wednesday 22nd December 2021 and will reopen at 8am Tuesday 4th January 2021. If you need us urgently during the break please email...