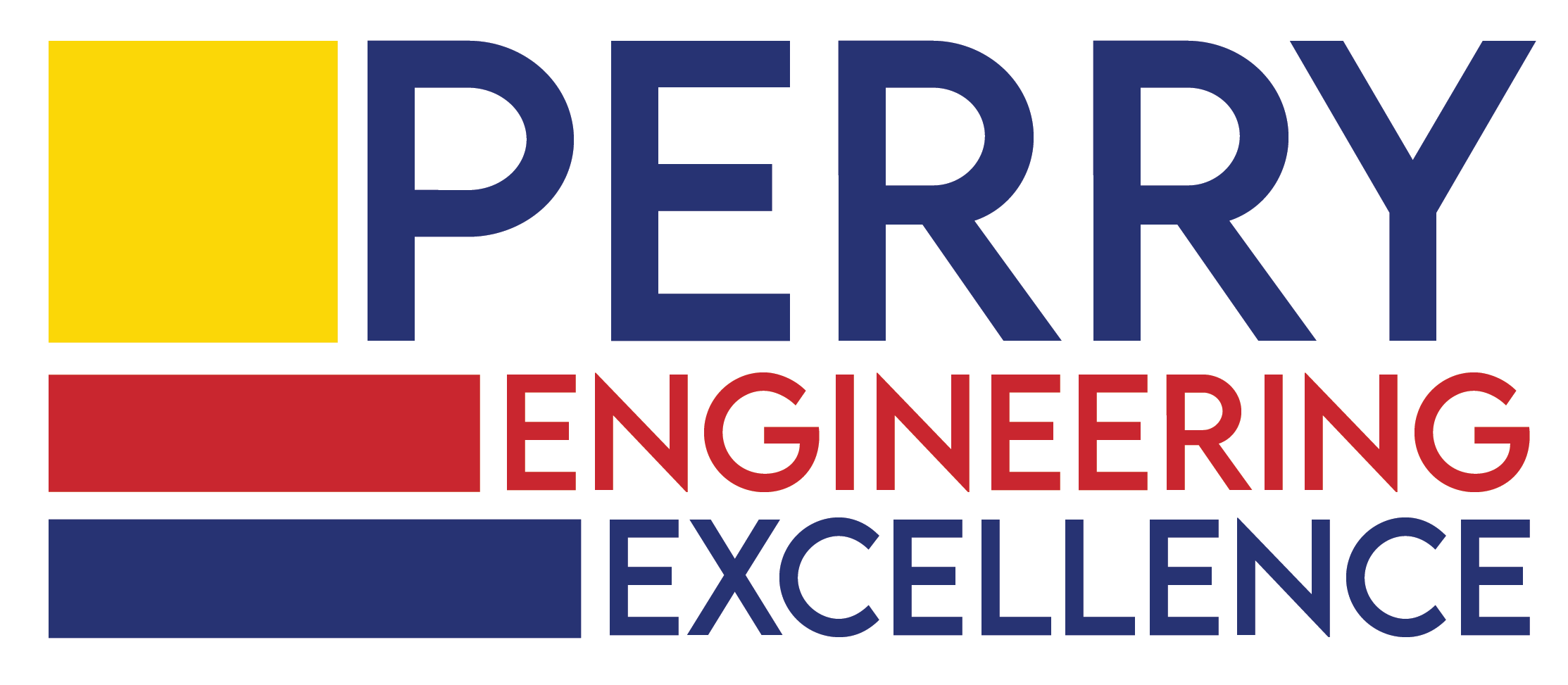

Mechanical Reception Hoppers & Trench Intake Conveyors

The range includes two different intakes with full compatibility with the Perry range of chain and flight conveyors. These are mechanical reception hoppers & trench intakes and both are suitable for free flowing products.

Mechanical reception hoppers are suitable for both above and below ground use and can also be made into mobile receptions. Trench intakes have been designed to reduce time spent loading mobile Grain Dryers and are designed to be installed within a pit without a product catchment hopper. Both types of intakes are manufactured from durable galvanised steel and have been designed to the same high specification as our chain & flight conveyor range.

Reception Hopper

- Can only be used for free flowing products.

- Manufactured in lengths from 3m to 6m (industrial up to 8m) and double this when units are used in tandem.

- Hoppers enable trailers to be tipped into a mechanical pit above ground. This is especially useful when there is a high water table and deep pits are not possible. Alternatively hoppers can be situated below ground to allow drive over access.

- The civil works only require a simple rectangular pit.

- Mobile machines are also available.

- Hoppers can be fitted to almost any Perry chain and flight conveyors giving complete flexibility.

- Galvanised construction is standard for all capacities up to 800tph.

- Inverter control is not required as there are two separate control slides with operating handles for flow control.

- Curved machines in conjunction with flight conveyors allow many different configurations.

Trench Intake

- Can only be used for free flowing products.

- more cost effective alternative to a reception hopper.

- Lengths from 1.5m upwards.

- Narrow and compact, perfect for existing trenches.

- No intake hopper, unless requested as an optional extra.

- Capacities up to 800tph.

- Requires an inverter to control the product flow rate.

- Compatible with most portable Dryers.

- Designed to reduce time spent loading a Dryer.

- Optional Hopper to increase product catchment area.

Pre-formed concrete trenches available for mechanical intakes.

Click here for more information

Videos

How To Drive Down Your Grain Drying Costs

We cover everything you need to know about Perry of Oakley Silos. Contact us today to discuss which silo is best for your requirements.

Which Type of Grain Dryer Should I Buy?

With over 70 years of experience, Perry of Oakley Ltd. are the UK’s most experienced manufacturer of materials drying and handling equipment. Our Dryers are relied on to manage a variety of crops, and in different climates all over the world.

Why Buy a Perry Mistral Grain Dryer?

More efficient drying and handling equipment can be used to save medium sized farms time and money while improving satisfaction within the workplace.