About Us

A 3rd Generation Family Run Business

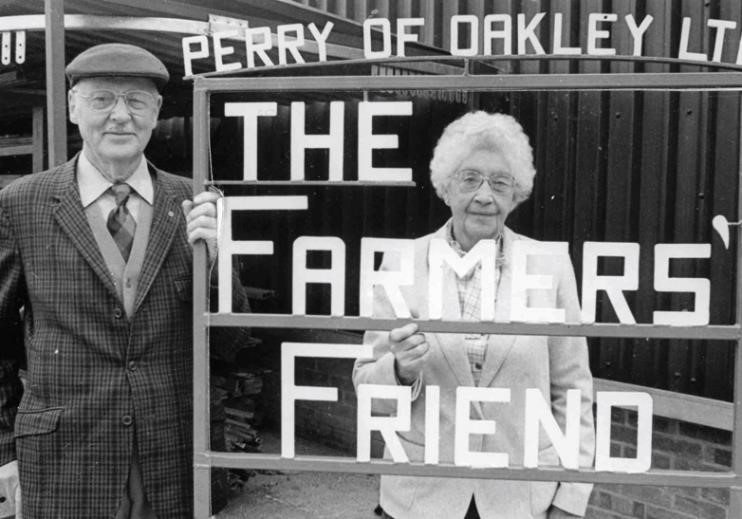

Tom Perry, a farmer’s son, founded the company back in 1947, by offering a mobile repair and manufacturing service to local farmers in Oakley, near Basingstoke in Hampshire.

That grew and in 1972 Nigel, Tom’s son joined the business and in 1974 they moved into a new purpose built facility in Oakley.

Nigel and his wife Pat made the huge decision to move the company down to Devon in late 1989 to enable its continued growth. Quickly after that their son, David, joined fresh from his 1st class Honours degree in Agricultural Engineering.

In 2007 David took over as MD, and continued the company expansion his dad had started. Since then the company product range and the number of countries they export to has grown significantly.

Claire, David’s sister, joined full time in 2020 to run the operational side of the company bringing her international corporate experience with her.

David & Claire have huge plans for the company so watch this space.

Our Team

Our technical sales & support teams have over 400+ years of experience in the bulk materials handing, drying & storage field, making the best team in the industry.

You can find the details of the Technical Sales team here.

The photo is of a few of us at Lamma the UK’s Premier Agricultural Machinery & Technology Show held annually at the NEC.

Our Factory Site

We moved to our current site, in a small village in rural Devon, back in 1989. Since then we have grown significantly and have purchased the land & buildings behind the main factory as they have come on the market.

The site is now spread across 8 buildings and over 3 acres.

It’s not the prettiest set up you’ll ever see, but it is a hardworking manufacturing site committed to delivering Engineering Excellence.

Products

Our product range includes; continuous mixed flow Dryers, belt Dryers, moisture sensor systems, chain & flight conveyors, belt conveyors, belt & bucket elevators, screw conveyors & augers, aspirator pre-cleaners, twin trace conveyors, grain samplers and bins/silos.

All Perry products are designed and manufactured to meet customer needs. We create and plan full site proposals, design and manufacture the machines in house and can offer full installation and commissioning service packages. We continue to support our machines throughout their life with comprehensive parts and service departments ready to look after customers, old and new.

The full range can be viewed on the Product page

Industries

Some of the key industries we have worked with include:

- Agriculture (farms & commercial grain stores),

- Feed mills,

- Flour mills,

- Flaking mills,

- Waste & recycling (SRF/RDF),

- Food recycling,

- Pelleting plants,

- Aggregates and

- Biomass (woodchip, shavings & sawdust).

The full range of Industries our equipment can be used for can be found here on the Industries page

We are very happy with the new sampling equipment, it’s a really nice machine. We are particularly impressed with the joystick controlled panel which we can program with up to ten sampling spots. It’s a big improvement on our previous system.

How Our Grain Sentry Moisture Control System Can Improve The Efficiency Of Your Grain Drying

The Grain Sentry Moisture Control system is used by farmers and grain stores that need to store large quantities of grain for extended periods. It helps to ensure that the grain is stored under optimal conditions, maintaining its quality and value. As a team with...

Everything You Need To Know About Perry Of Oakley Silos

We cover everything you need to know about Perry of Oakley Silos. Contact us today to discuss which silo is best for your requirements.

Why Trust Matters – 70 Years Of Engineering Excellence

Here at Perry’s, we’re the only UK company that manufactures a full range of both bulk materials handling and drying machinery. The handling equipment is capable of capacities from 8tph (agricultural specification) to 1200tph (industrial specification) and includes...