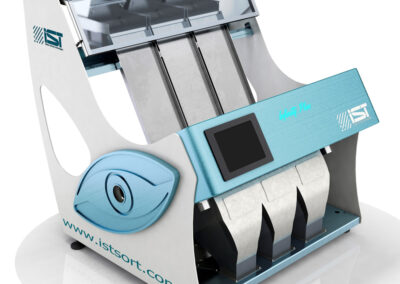

Colour Sorters

Perry provide an optical Colour Sorter range which consists of cost effective, high capacity, machines featuring either the latest full colour RGB (Red, Green, Blue) technology or the more accurate Near Infrared technology.

IST Colour Sorter Demo:

Removing Ergot From Wheat

In this 2 minute video we will show you just how easy the IST Colour Sorter is to use and how effectively it removes impurities from your grain.

How it works

The products to be sorted drop by gravity on the chute and are inspected by a series of digital cameras that are able to recognise any defect in the product. Once the defect has been recognised, a blow of compressed air deflects it, bringing it to the waste collection area.

That defect can be in size or colour, organic or inorganic.

What makes these colour sorters so good?

These optical sorters are able to detect any defect in the inspected material, using digital cameras at high resolution able to distinguish 16 million colors and imperfections up to 0.09 mm. This is possible thanks to the full color and trichromatic technology, which allows the camera lenses to replicate the human eye’s ability to distinguish even the smallest shade of colour.

In addition the colour sorters cross recognise in size and colour. This double evaluation allows you to select the materials by limiting the processing waste as much as possible and, consequently, increasing the quality of the final product.

What capacity can they do?

The range has sorters from 1 chute through to 8 chutes with ~ 4-6tph capacity on wheat per chute.

The actual capacity is governed by the characteristics of the product and the level of contamination present.

But, chute sizes vary between manufacturers so don’t be caught out. For example our 6 chute has the same capacity as another well know brand’s 8 chute.

Who’s the manufacturer?

The Perry range of colour sorters are designed and manufactured by IST Technologies in Italy. Just like Perrys they develop their product ranges in-house including the software so they can easily answer any queries.

The Perry team have invested in training up our technical support team in the UK in the operation of the IST colour sorters and also hold a stock of spare parts in their UK based factory so speedy support can be given.

We have significant experience with installing, commissioning, & supporting IST colour sorters so you can be assured you will get the same level of support for them from us as you do for any of the Perry ranges.

What products can the colour sorters work on?

That is an excellent question as the answer is a lot!

They will work on grains, pulses, dried fruits, coffee beans, seed selection, plastics, metals & minerals.

How do I integreate thme into my line?

As we manufacture a wide range of bulk materials handling & storage machinery we can fully integrate a colour sorter into your faclity.

Just contact us today with your requirement

8 Chute Colour Sorter Video

In this 1 minute video you’ll see an operational 8 chute colour sorter in a grain store, actively sorting impurities from a load of grain.

It’ll show you a sample of the clean grain coming out, and a sample of the impurities being rejected.

The accuracy of the IST sorters is very high so it has a low false rejection rate.

Everything You Should Know About Grain Sentry Fire Detection

With over 40 years of experience, Fire Shield Systems offer a holistic approach to fire protection encompassing design, installation, maintenance and training.

Which Type of Grain Dryer Should I Buy?

With over 70 years of experience, Perry of Oakley Ltd. are the UK’s most experienced manufacturer of materials drying and handling equipment. Our Dryers are relied on to manage a variety of crops, and in different climates all over the world.

Why Buy a Perry Mistral Grain Dryer?

More efficient drying and handling equipment can be used to save medium sized farms time and money while improving satisfaction within the workplace.