Flaking, Roller and Hammer Mills

Within a milling application, after going through a steam chest, the product will enter either a flaking, roller or hammer mill. A flaking mill pushes the product through two rollers to make a flake. A roller mill will crack the product. A hammer mill is roller with a series of hammer-shaped instruments inside – the product falls through and creates a powder as it leaves.

Key Points

- Available sizes: 18”x24”, 18”x36”, 24”x36”, 24”x48”, 24”x56”.

- Quality, consistent flake production.

- Heaviest mill in the industry.

- Stainless steel roll covers.

- Stainless steel peg-feeder with VFD drive.

- Best quality rolls and shafts.

- Heavy duty TEFC motors.

- Exclusive belt tensioning system.

- Fixator type roll gap adjustment.

- Frame machined to exact tolerances.

- All bearings have a central greasing system.

- OSHA type belt guards.

- Adjustable spring loaded scraper blades.

- Hydraulic roll closure system.

Everything You Should Know About Grain Sentry Fire Detection

With over 40 years of experience, Fire Shield Systems offer a holistic approach to fire protection encompassing design, installation, maintenance and training.

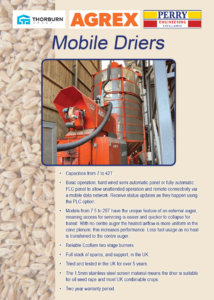

Which Type of Grain Dryer Should I Buy?

With over 70 years of experience, Perry of Oakley Ltd. are the UK’s most experienced manufacturer of materials drying and handling equipment. Our Dryers are relied on to manage a variety of crops, and in different climates all over the world.

Why Buy a Perry Mistral Grain Dryer?

More efficient drying and handling equipment can be used to save medium sized farms time and money while improving satisfaction within the workplace.