Save Up To 35% of Your Dryer Operating Costs*

To maximise your Grain Dryer operating cost savings we strongly recommend these 3 key products are fitted to your Dryer

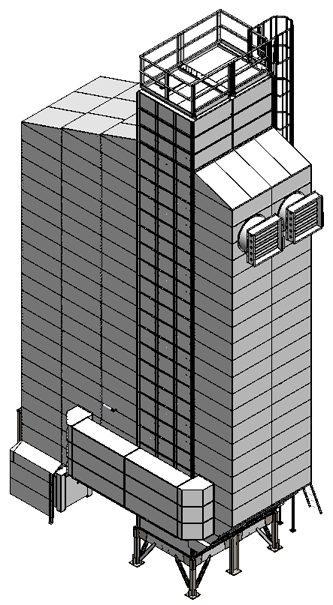

Hot Air Recirculation

The operating cost savings come from the reduction in the amount of fuel the Dryer consumes to heat the air to dry the grain.

Depending on the Dryer size, 25% to 30% of the warmest air in the Dryer is moved by the recirculation fan along transfer ducts to an additional plenum and mixed with the freshly heated ambient air.

This Hot Air Recirculation can save you up to 24% of your Grain Dryer fuel costs.

For full details on Hot Air Recirculation click here

Grain Dryer Moisture Monitoring System

The Perry Automatic Dryer Moisture Monitoring System, The Grain Sentry, controls not only Dryer speed, but also Dryer temperature.

This is achieved by measuring the grain moisture going into, and, coming out of the Dryer, using one of the most accurate Near Infra Red moisture meters available on the market, which does not require calibration.

This prevents the quite large losses associated with over drying grain such as, loss in weight, extra fuel use, labour and electricity. This means big savings and peace of mind can be achieved.

For full details on The Grain Sentry click here

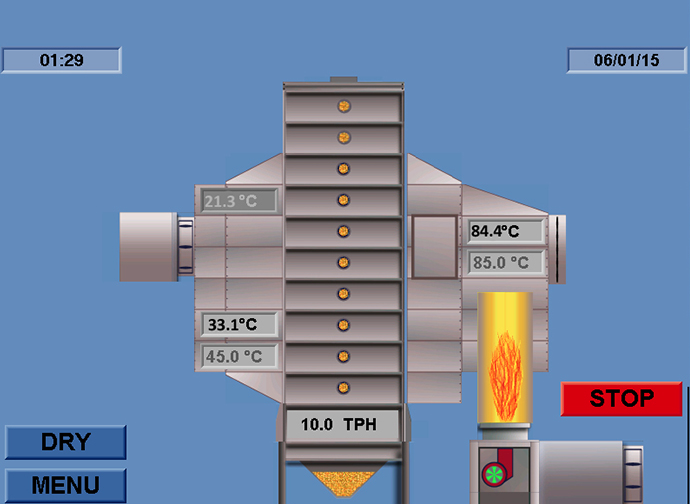

Grain Dryer PLC Panel

The touch screen panel comes with over 70 alarms and messages that can be displayed on the screen and sent to a mobile phone providing the panel is connected to the internet.

The combination of the alarms, messages and remote connectivity will reduce the labour requirement to running and monitoring the Grain Dryer.

All the programing of the panel is completed by the Perry in-house engineering team so support is readily available whenever you should need it.

For full details on Dryer PLC Control Panel click here

The level of cost savings you should expect?

*In reality the level of savings will be down to your specific set up and will vary based on numerous factors including ambient conditions, crop type & moisture, current fuel costs and so on.

Contact us today and we can run your details through our Dryer Cost Savings calculator and see what is theoretically possible for your Dryer.

How To Drive Down Your Grain Drying Costs

We cover everything you need to know about Perry of Oakley Silos. Contact us today to discuss which silo is best for your requirements.

Which Type of Grain Dryer Should I Buy?

With over 70 years of experience, Perry of Oakley Ltd. are the UK’s most experienced manufacturer of materials drying and handling equipment. Our Dryers are relied on to manage a variety of crops, and in different climates all over the world.

Why Buy a Perry Mistral Grain Dryer?

More efficient drying and handling equipment can be used to save medium sized farms time and money while improving satisfaction within the workplace.