Reduce Your Dryer Operational Costs By Up To 35%

These 3 add-ons combine to save you up to 35% of your Dryer operational costs

Maximise Your Operational Savings

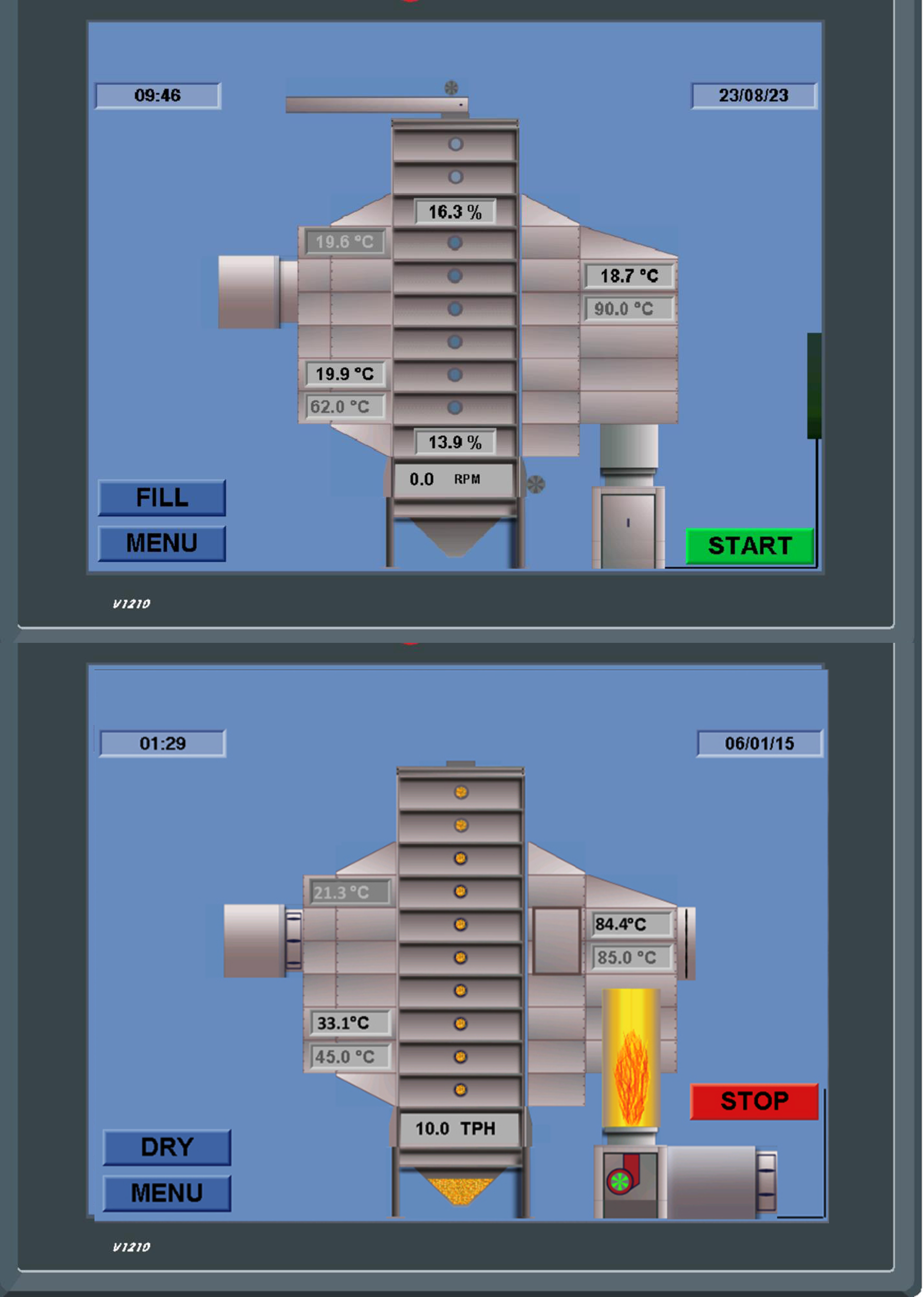

Hot Air Recirculation can save you up to 24% of your Grain Dryer fuel costs by recirculating the cooling air from the lower levels of the Dryer to the hot air side of the Dryer and remixing it with heated air.

To find out more click here

Grain Sentry Automatic Grain Moisture Monitoring can save £21,500 per season on direct drying costs for a 30tph throughput Dryer drying 6000T per season in average conditions. It does this by controlling the Dryer temperature and discharge speed automatically by measuring the input and output grain moisture content using clever tech.

To find out more click here

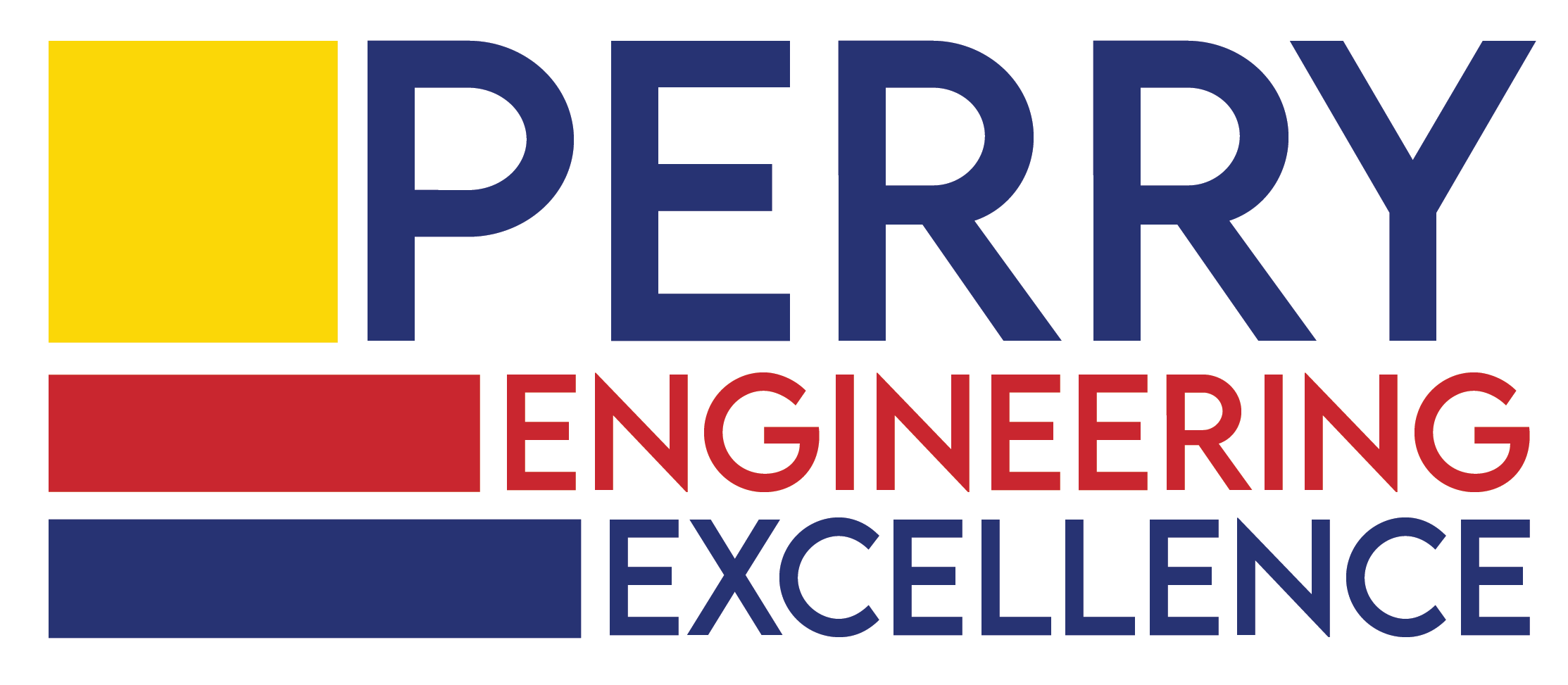

Grain Dryer Control via PLC Panel is a 12″ touch screen that controls the Dryer operation. It’s designed with over 70 alarms and notifications so providing it is hooked up to the internet you can leave the Dryer running and recieve alerts via an app on your phone if there’s a porblem. This cuts down on the manpower needed to run and monitor the Dryer.

To find out more click here

Which Grain Dryer Will Suit Your Needs?

Contact us today to discuss how you can save 35% of your operational Dryer costs

Call us on +44 (0)1404 890300 or email [email protected]

PERRY DURING COVID-19

Managing Director, David Perry, said “It is imperative that our British farmers are able to continue to support this country through these uncertain times, as a company we aim to support them every way we can with the help of our trusted dealer network. From new...

TRENCH AND MECHANICAL INTAKE PITS: SELECTING THE CORRECT INTAKE CONFIGURATION FOR YOUR FACILITY

When considering which type of mechanical intake system to use, the first thing to consider is the type of products to be handled. If the products are all free flowing such as cereals, then a chain and flight conveyor system will...

SEASONS GREETINGS FROM PERRY OF OAKLEY LTD.

Wishing you a fantastic festive period, and a Happy New Year, from all at Perry! Our factory will close at 5pm on Wednesday 22nd December 2021 and will reopen at 8am Tuesday 4th January 2021. If you need us urgently during the break please email...