Reduce Your Dryer Operational Costs By Upto 35%

These 3 add-ons combine to save you up to 35% of your Dryer operational costs

Maximise Your Operational Savings

Hot Air Recirculation can save you up to 24% of your Grain Dryer fuel costs by recirculating the cooling air from the lower levels of the Dryer to the hot air side of the Dryer and remixing it with heated air.

To find out more click here

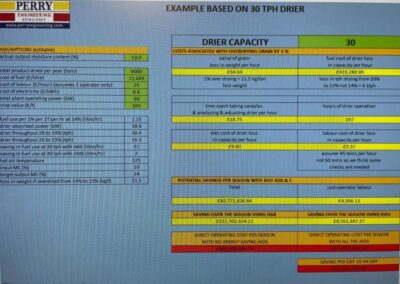

Grain Sentry Automatic Grain Moisture Monitoring can save £21,500 per season on direct drying costs for a 30tph throughput Dryer drying 6000T per season in average conditions. It does this by controlling the Dryer temperature and discharge speed automatically by measuring the input and output grain moisture content using clever tech.

To find out more click here

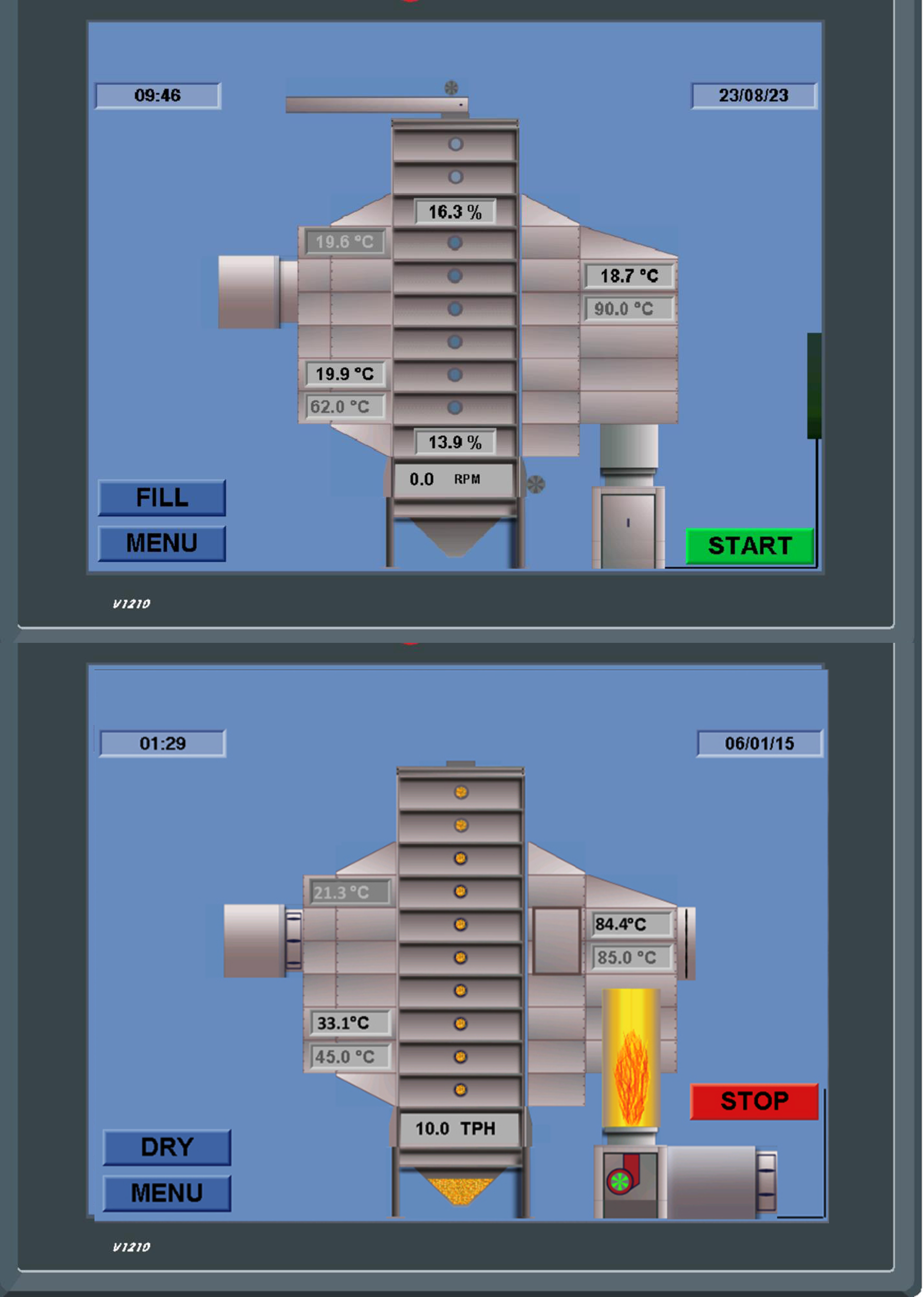

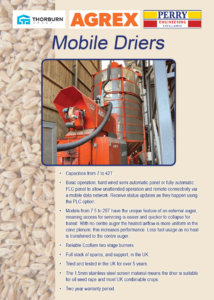

Grain Dryer Control via PLC Panel is a 12″ touch screen that controls the Dryer operation. It’s designed with over 70 alarms and notifications so providing it is hooked up to the internet you can leave the Dryer running and recieve alerts via an app on your phone if there’s a porblem. This cuts down on the manpower needed to run and monitor the Dryer.

To find out more click here

Which Grain Dryer Will Suit Your Needs?

Contact us today to discuss how you can save 35% of your operational Dryer costs

Call us on +44 (0)1404 890300 or email [email protected]

Everything You Should Know About Grain Sentry Fire Detection

With over 40 years of experience, Fire Shield Systems offer a holistic approach to fire protection encompassing design, installation, maintenance and training.

Which Type of Grain Dryer Should I Buy?

With over 70 years of experience, Perry of Oakley Ltd. are the UK’s most experienced manufacturer of materials drying and handling equipment. Our Dryers are relied on to manage a variety of crops, and in different climates all over the world.

Why Buy a Perry Mistral Grain Dryer?

More efficient drying and handling equipment can be used to save medium sized farms time and money while improving satisfaction within the workplace.